- Ask a question

- 02188621961

- 02188617645

- a_zm@Mail.com

Titanium

May 20, 2017curtain wall

June 21, 2017Composite sheet enconomy

Aluminum Composite Panels of ACP (Aluminum Composite Panels) are made of two layers of aluminum with thicknesses of 0.3-0.6 mm and a polyethylene inner core as a filler of thicknesses of 2 to 5 mm which is placed between these two layers. Which is usually coated with PVDF coating for exterior and polyester or for interior glazing.

Technical Features and General Aluminum Composite Sheet – Simplicity of implementation (installation) in the building view – Ability to change panels – Resistant to environmental changes in the environment – Plasticity – Color variation – Light weight

– Ability to sealing facade

-Non-integrated operation in the earthquake – No air erosion

The following table compares the performance of different materials with the aluminum composite sheet

| Row | Kind of materials | Weight (m²) | Component weight (m 2) | Total (m²) |

| 1 | Granite stone 3 cm | 80 Kg | 20 kg with iron plating | 100 Kg |

| 2 | Granite stone 3 cm | 80 Kg | 14 kg with mortar | 94 Kg |

| 3 | Cement with a thickness of 4 cm | 75 Kg | —- | 75 Kg |

| 4 | Glass 6 mm | 25 Kg | 12 kg with aluminum profile | 37 Kg |

| 5 | Aluminum sheet 3 cm | 75 Kg | 10 Kg | 85 Kg |

| 6 | Aluminum Composite Sheet | 6 Kg | 8 Kg | 14 Kg |

Types of Aluminum Composite Sheets

Simple composite

Nano composite

Antibacterial composite

Resistant composite

Spectral composite (colored)

Methods of execution

1- Fix method

In this system, after the implementation of the substructure, (mainly a grid of 40×40 and 40×20 steel profiles), the composite sheets (after cutting, grooving, bending and assembling) by aluminum cores or their turning edges with a bolt or rivet It is fixed on iron constructions.

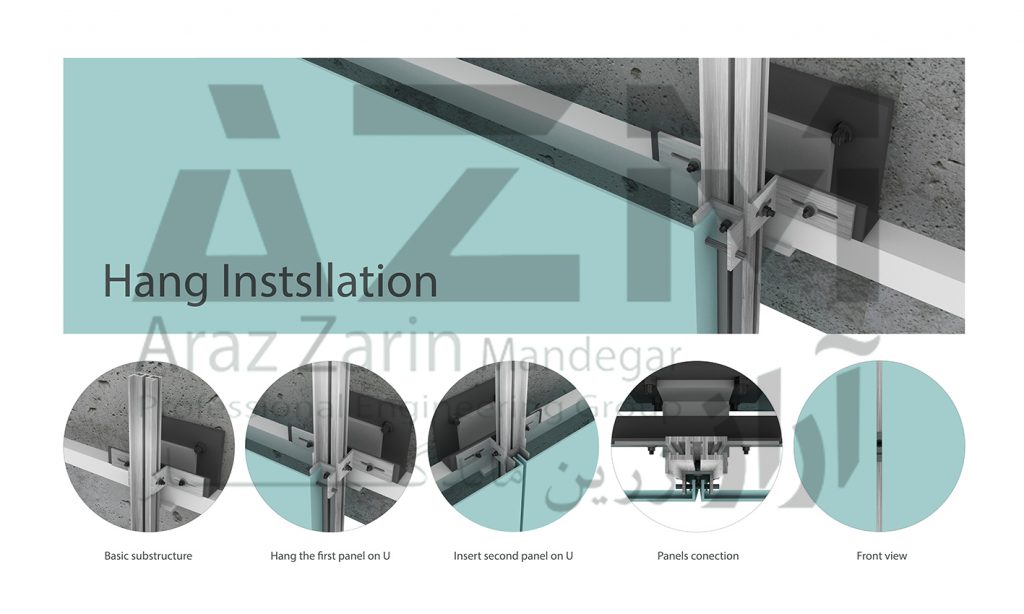

2- Hand Method (Hang)

In this system, the main profiles (aluminum studs) are made of aluminum beams made of beaked holes, and they are screwed into steel bolts and bolts, and small studs with pin stitches are placed in the main studs. On the edges of the sheets, the pins are replaced, and the sheets are hanging on the pin of small studs.

3- H & L Method

In this system after the implementation of the substructure, (mainly a grid of 40×40 and 40x20mm steel profiles), using aluminum profiles with cross section H, L and Kenji, the aluminum composite sheets are placed without the need for a return edge inside these sections. And framed.

4- Araz Zarin Mandegar Specialized Technique

In this system, after the implementation of the installation by metal profiles, using the company’s specialized aluminum profiles, this profile is first mounted with a screw or a rivet to the back edge of the sheet and the next sheet is placed as a slider inside the profile. The advantages of this system are not a bolt or a rivet in June.